Differential global positioning system (DGPS) surveys are advanced geospatial data collection methods used to enhance the accuracy of location information, especially critical in areas like pipeline management within industries such as oil, gas, and utilities.

DGPS surveys correct systematic errors in standard GPS data, providing precise mapping of pipeline routes. This high precision aids in design, installation, and maintenance and ensures regulatory compliance.

These surveys are important because they underpin pipelines’ safe and efficient operation that transports essential resources like gas, oil, and water.

If you live near, work with, or are responsible for managing such infrastructure, understanding DGPS surveys can provide insight into risk mitigation, cost management, and long-term planning strategies.

These surveys also indirectly contribute to the stable and secure supply of crucial utilities consumers use daily.

In this article, we will dive deeper into the topic of DGPS surveys to cover what they’re used for, how long they take, and who’s involved in the process.

What is a Pipeline DGPS Survey?

A pipeline DGPS Survey, or differential global positioning system survey, is a precision method utilized to obtain the exact geographical coordinates of pipelines. The DGPS technology enhances the accuracy of the standard GPS by correcting errors resulting from the signal delay due to the ionosphere and troposphere and satellite and receiver clock errors.

In a pipeline DGPS survey, the precise location of the pipeline, both horizontally and vertically, is recorded. These geographical points are logged continuously or at intervals, as the surveyor traverses the pipeline route, comprehensively mapping its position and topography.

This type of survey is crucial, as it helps in the planning and design stages of a pipeline construction project. Accurate data helps to avoid potential obstacles, reduce risks, and provide cost-effective solutions.

Post-construction, these surveys are essential for the effective management, maintenance, and future development of the pipeline system, ensuring public safety and regulatory compliance.

How Does DGPS Work?

A differential global positioning system (DGPS) is a method that enhances GPS accuracy by correcting many systematic errors. These errors can be due to signal delay caused by the ionosphere and troposphere, satellite and receiver clock inaccuracies, and orbital errors.

DGPS uses a network of fixed, ground-based reference stations to broadcast the difference between the positions indicated by the GPS satellite systems and the known fixed positions.

These stations receive GPS signals and compare them to the known location. If an error is identified, a correction factor is calculated and transmitted to the GPS receivers in the area.

A GPS receiver compatible with DGPS can then apply this correction factor to its position calculation, enhancing the precision of its readings. As a result, DGPS can provide location accuracy within one to three meters, while standard GPS accuracy is typically within five to ten meters.

Implementing DGPS is vital in various applications, including precision agriculture, surveying, construction, and marine navigation. By minimizing systematic errors, DGPS ensures high positional accuracy, increasing reliability and effectiveness in these fields.

What is the Process of a Pipeline DGPS Survey?

A pipeline differential global positioning system (DGPS) survey involves several meticulous steps to map pipeline locations accurately.

Step 1: Preparation

Before the survey begins, it’s important to take the proper steps to prepare. The survey team must review the project’s specifications, obtain necessary permits, and prepare the equipment needed.

Step 2: Baseline Survey

DGPS receivers are set up along the pipeline route at predetermined locations. They collect raw data, which is further processed to obtain the precise coordinates of these control points.

Step 3: Field Data Collection

Surveyors traverse the pipeline route, recording the geographical coordinates at regular intervals or continuously. This includes both horizontal and vertical positioning data of the pipeline.

Step 4: Data Processing

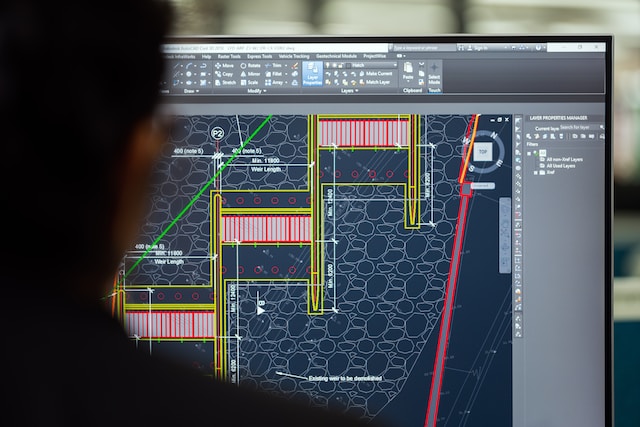

The raw data collected is processed using specialized software. This involves comparing the data from the roving receiver with that of the stationary receiver to compute a corrected, high-accuracy position.

Step 5: Analysis

The processed data is analyzed to generate a comprehensive map that indicates the pipeline’s exact location. This map can be used for planning, design, management, and maintenance.

Step 6: Reporting

The final report, which includes all collected data, observations, and graphical representations, is prepared and handed over to the concerned authorities or clients. This process ensures accurate and precise measurements, facilitating the safe and efficient installation and management of pipeline systems.

How Long Does a Pipeline DGPS Survey Generally Take?

The duration of a pipeline DGPS survey can vary greatly depending on several factors, including the length and complexity of the pipeline route, the terrain, the accuracy requirements, and the specific regulatory environment.

A pipeline DGPS survey might take a few days to a week for a simple survey on relatively flat terrain and clear surroundings. This timeline includes preparation, data collection, processing, and report creation.

However, the survey could extend from several weeks to a few months for more complex projects involving longer distances, challenging terrains like mountains or urban areas, or when dealing with sensitive environmental regions.

Each section of the pipeline route must be thoroughly surveyed, and any obstacles or challenges must be accurately documented.

Data processing and analysis time may also vary. This depends on the volume of data collected, the precision required, and the software used.

Ultimately, the timeline for a pipeline DGPS survey should ensure that the most accurate and reliable data is gathered and interpreted correctly to ensure the pipeline’s safe and efficient installation, operation, and maintenance.

Why Are Pipeline DGPS Surveys Useful?

Pipeline differential global positioning system (DGPS) surveys are indispensable in the oil, gas, and utilities industries. They serve numerous purposes, including enhancing precision, reducing risk, boosting cost-effectiveness, and more.

Precision

DGPS provides a significantly higher accuracy level than standard GPS. This precise data is critical in designing and constructing pipelines, as it enables accurate mapping of the pipeline’s location horizontally and vertically.

Risk Reduction

Accurate mapping helps avoid potential obstacles and reduces pipeline construction and maintenance risks. It aids in detecting geographical features that could impact the pipeline’s integrity, thereby mitigating potential hazards.

Cost-Effectiveness

By identifying the most efficient routes and potential obstacles in advance, these surveys help minimize construction and maintenance costs, making the process more economical.

Regulatory Compliance

Complying with regulations requiring accurate pipeline route location data is crucial. DGPS surveys help in maintaining such standards, ensuring safety and regulatory compliance.

Maintenance and Management

Post-construction, DGPS surveys are used for the ongoing management and maintenance of pipelines, identifying potential problem areas, and aiding in quick, precise responses to issues. Maintenance, management, and upkeep are important parts of pipeline construction.

Future Planning

The data from these surveys can be used in future planning for pipeline upgrades, rerouting, or decommissioning, making them a vital tool for long-term infrastructure management.

Who is Involved in Pipeline DGPS Surveys?

A pipeline DGPS survey involves a range of professionals who each play a critical role in ensuring the successful completion of the survey. Here are the key personnel involved:

Surveyors

These professionals perform fieldwork, traveling the pipeline route and using DGPS equipment to collect geographical data.

Geodesists/Geomatics Engineers

Geodesists and geomatics engineers are experts in measuring and interpreting the earth’s physical and cultural features. They oversee the planning, execution, and verification of the survey data accuracy.

GIS Analysts

GIS analysts are in charge of managing, processing, and analyzing the geographical data collected from the survey, often using specialized software to generate accurate maps and models.

Data Processors

These professionals work closely with GIS analysts to clean, validate, and transform raw data into a usable format. They facilitate the analysis of data by making it easier to consume.

Project Managers

Project managers are tasked with overseeing the entire survey project, coordinating with various teams, ensuring compliance with regulatory standards, managing the budget, and ensuring the project stays on schedule. Without them, there would surely be delays.

Client Representatives

These are individuals from the organization that commissioned the survey. They define the survey requirements and use the collected data for planning, design, and maintenance purposes. Client representatives (and the clients themselves) are important stakeholders throughout this process.

Regulatory Authorities

While not directly involved in the survey, regulatory authorities set the standards for pipeline installation and maintenance and evaluate the final results for compliance.

Through their combined efforts, each of these professionals ensures the survey’s success, contributing to pipeline systems’ safe and efficient operation.

FAQs

What is the use of DGPS in surveying?

Differential global positioning systems (DGPS) are used in surveying to improve the accuracy of positional data collected.

By utilizing a network of stationary reference stations to correct the inherent errors in GPS data, DGPS can achieve a high level of accuracy, typically within one to three meters. This precision is invaluable in applications like topographic mapping, construction, mining, and other fields where accurate geospatial data is critical.

What is DGPS in oil and gas?

In the oil and gas industry, DGPS is used to precisely locate exploration sites, drilling platforms, and pipeline routes. Accurate positioning is vital for these operations to ensure safety, efficiency, and regulatory compliance.

Moreover, DGPS is used in offshore operations for navigating vessels and remotely operated vehicles (ROVs), ensuring precise positioning even in challenging marine environments.

What does DGPS mean for pipeline surveys?

In the context of pipeline surveys, DGPS provides the highly accurate mapping of pipeline routes. By collecting and correcting GPS data, surveyors can ascertain a pipeline’s exact horizontal and vertical position, which aids in its design, installation, management, and maintenance.

It helps in risk mitigation, planning for future developments, and ensuring public safety and regulatory compliance.

Final Thoughts

In conclusion, pipeline differential global positioning system (DGPS) surveys are integral to pipeline management, playing a crucial role in the oil, gas, and utilities industries. These surveys significantly enhance positional data’s accuracy, providing precise mapping of pipeline locations both horizontally and vertically.

This high level of precision is crucial in mitigating risks, ensuring cost-effectiveness, facilitating compliance with regulatory standards, and aiding in the efficient management and maintenance of pipelines. Moreover, DGPS surveys prove instrumental in future pipeline upgrades, rerouting, or decommissioning plans.

Professionals such as surveyors, geodesists, GIS analysts, data processors, and project managers are all involved in ensuring a successful survey. From exploration sites to drilling platforms, especially in pipeline management, the importance of DGPS cannot be overstated.

Whether it’s the simplicity of flat terrain or the complexity of a sensitive environmental region, DGPS surveys ensure the safe, efficient, and accurate operation of pipeline systems.