The Fourth Industrial Revolution (or Industry 4.0) is rapidly transforming society, economies, and different industries. A key component of Industry 4.0 is interconnectivity and the increasing integration of virtual and physical environments. This has led to the emergence of new technologies, like the metaverse, advanced simulations, and digital twin technology.

Digital twin technology—which serves as the real-time virtual counterparts of physical objects, processes, and services—is transforming industries and professions as varied as oil and gas; architecture, engineering, and construction (AEC); manufacturing; software development; and systems engineering.

Systems engineering—which is a transdisciplinary and integrative approach to designing, integrating, and managing complex systems over their life cycles—benefits immensely from the use of digital twin technology. Digital twin technology is particularly impactful for projects that are built and managed using the model-based systems engineering (MBSE) approach.

In this article, we’ll discuss MBSE in greater detail. We’ll also examine how digital twin technology is transforming systems engineering, how it’s benefitting this interdisciplinary field, and the future of this technology in systems engineering.

What is Model-Based Systems Engineering?

Model-based systems engineering (MBSE) is a technical approach to systems engineering that focuses on domain models as the main conduit for information exchange. MBSE can also be described as a methodology that supports the system requirements, design, analysis, validation, and verification of complex systems. This formalized application of modeling guides all activities throughout the development lifecycle.

MBSE places models at the center of system design. This is in stark contrast to document-centric engineering, which uses documents to design, implement, and harness the information used in systems engineering processes.

Since digital-modeling environments have been shown to improve outcomes for development projects, they’re used to streamline highly complex and difficult projects. In fact, MBSE can result in a 55% reduction in total development costs when applied correctly to systems engineering projects.

MBSE applies visually and semantically-rich modeling languages to core systems to reduce complexity, as well as align stakeholders, processes, and technological solutions towards a common goal.

System-modeling languages can generally be divided into two categories: general-purpose and specialized. Some of the most widely used general-purpose modeling languages include the Systems Modeling Language (SysML) and the Unified Modeling Language (UML). Architecture Analysis Design Language (AADL) is an example of a widely used specialized modeling language.

MBSE integrates three key concepts: models, systems thinking, and systems engineering.

- Models – These are simplified versions of entities. They can be graphical, physical, or mathematical representations that are designed to reduce complexities.

- Systems thinking – This systematic framework analyzes systems as part of much larger, integrated systems rather than as self-sufficient entities.

- Systems engineering – This is the interdisciplinary field of engineering that facilitates the successful realization, use, and retirement of engineered systems.

How Do You Apply Digital Twin Technology to Systems Engineering?

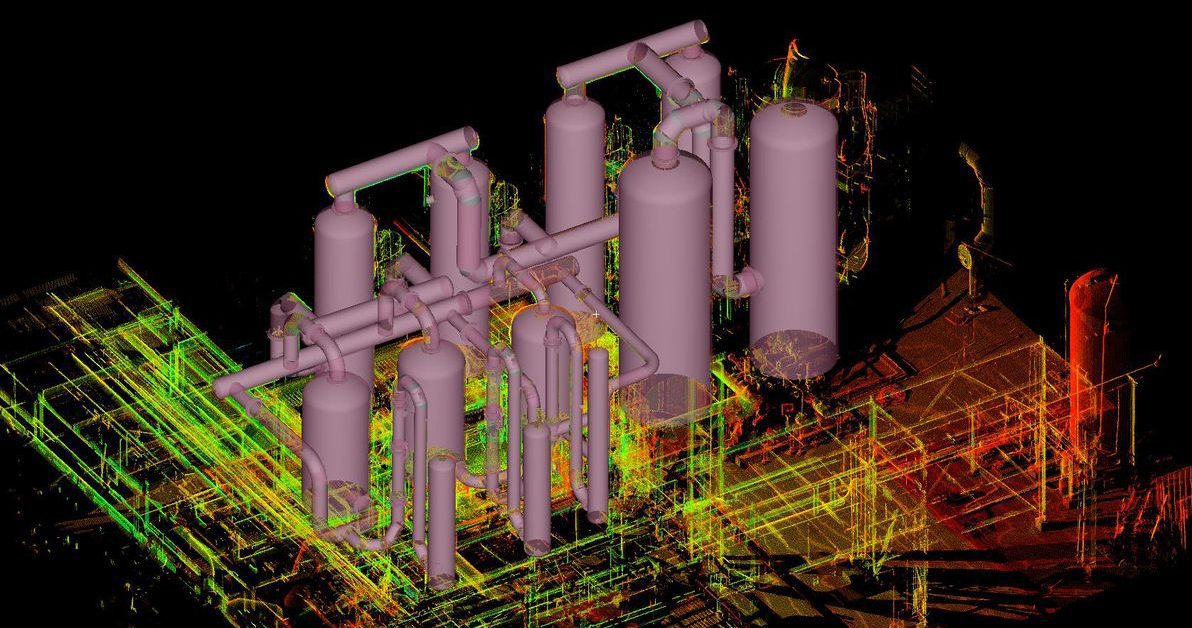

When utilized in a model-based systems engineering (MBSE) framework, digital twin technology can be used to test the behavior of virtual prototypes in “what-if” simulations under the control of the systems engineer. Data is transferred from the physical object to its digital twin, and both interconnected entities are fed with additional data from MBSE tools and data acquisition tools.

Both the MBSE and data acquisition tools, in turn, are connected to the MBSE system lifecycle. Examples of MBSE tools that can be connected to the system lifecycle include system modeling tools, verification tools, and SysML models. These are applied with operational scenario simulations (such as agent-based and discrete event simulations) to explore the behavior of digital prototypes in hypothetical virtual scenarios.

What are the Benefits of Digital Twins for Systems Engineering?

When applied correctly to systems engineering projects, digital twins can dramatically improve the success rate of projects, as well as reduce the cost of system design activities. The likelihood of success is increased when digital twin technology is integrated with the systems engineering process, its supporting infrastructure, and the stakeholders that provide ongoing input.

Using data gathered from internet-enabled sensors, drones, cameras, high-definition survey/laser scanners, and other devices, system simulations can be run to explore failure modes. This leads to progressive design and system improvements over time.

For example, a computer manufacturer could link a digital twin to its physical counterpart’s service history, manufacturing process, design history, interconnected device and internet-enabled sensor data, projected failure modes, and configuration-specific simulation models using MBSE tools. The computer manufacturer could then compare simulation outputs to results in the real world, providing valuable insights about the physical prototype.

Overall, the insights gathered from simulation outputs could inform an array of disciplines, including business and product development, manufacturing and operational efficiencies, and predictive maintenance.

Just as importantly, the use of digital twin technology in MBSE-based frameworks can also facilitate the discovery of new application opportunities and revenue streams. Using digital twins, different versions of the system can be evaluated to determine which iteration provides the most operational efficiency.

When integrated with machine learning and other data science technologies, large amounts of data can be analyzed and new application opportunities and revenue streams can be correctly identified and harnessed.

Listed here are the additional benefits to applying digital twins in systems engineering frameworks:

- Enhanced traceability – The digital thread that connects the digital twin to its physical counterpart also promotes traceability between lifecycle phases.

- Remote troubleshooting – Maintenance personnel can troubleshoot malfunctioning equipment remotely.

- Diagnostic testing – Since the digital twin accurately mirrors its physical counterpart’s current condition, it can be used to perform diagnostic testing.

What is the Future of Digital Twins in Systems Engineering?

Digital twin technology is on track to becoming a central component in the model-based systems engineering (MBSE) framework. Aside from allowing MBSE to encompass the full system lifecycle, digital twins also allow MBSE to penetrate new markets, such as real estate, manufacturing, and construction. MBSE can also bolster digital twin simulations via system modeling constructs and system modeling languages.

Within MBSE frameworks, digital twin technology can be applied to upfront engineering (including model verification and system conceptualization), smart manufacturing, testing (e.g. model-based system validation), and system maintenance (e.g. condition-based maintenance).

Digital twin technology will continue to gain prominence in the real estate and construction industries because real-time access to systems data is essential for adaptive energy management.

Predictive maintenance is another major area of growth for digital twin technology as many organizations are shifting from schedule-based maintenance to condition-based maintenance. The digital twin model’s ability to reflect the real-world condition of its physical counterpart allows personnel to accurately schedule repairs and replace parts before they break down.

The digital thread—which facilitates the upstream and downstream transfer of data—allows systems engineers to accurately gauge system performance and diagnose technical risks. Within the MBSE framework, digital twins can become the single authoritative source of truth about the performance of complex systems over their life cycles.